Applications

Used in paper mills to efficiently remove and transport trim waste generated during the paper production process. These systems are crucial for maintaining clean and efficient production lines, preventing blockages, and ensuring smooth operation.

Benefits

Trim conveying systems enhance operational efficiency by automating the removal of trim waste, reducing manual handling and associated labor costs. They help maintain a cleaner production environment, minimize downtime due to trim-related blockages, and support waste recycling efforts.

Capacities

Trim Conveying Capacity: Capable of handling trim widths from a few millimeters to several centimeters

Air Flow Rates: From 1,000 to over 10,000 cfm

Conveying Distance: Effective over distances ranging from a few meters to over 100 meters, depending on the system design and layout

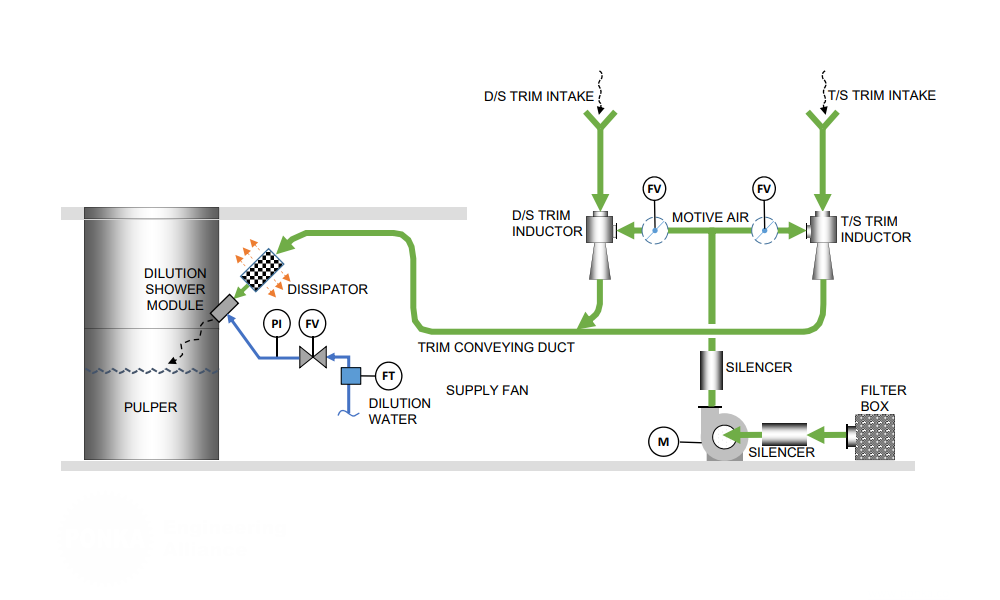

The injector-type trim conveying system uses high-velocity air to transport trim waste. The system consists of a series of air injectors positioned along the paper machine where trim waste is generated. When the trim is cut, the air injectors create a powerful airflow that captures and conveys the trim through a ductwork system. The trim is transported to a central collection point or baler for recycling or disposal. The air velocity and injector placement are carefully controlled to ensure efficient trim capture and conveyance, preventing trim from accumulating on the machine or production floor. This system ensures continuous removal of trim waste, maintaining optimal machine performance and cleanliness.

Related Systems

Please see the Pneumatic and Conveying Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.