Applications

Used to convey materials through ductwork in various industries, including manufacturing, food processing, pharmaceuticals, and chemical production. These systems are essential for transporting bulk materials, powders, granules, and other particulate matter efficiently and cleanly.

Benefits

Pneumatic feed systems enhance operational efficiency by providing a reliable and flexible method for transporting materials. They reduce the risk of material contamination, minimize spillage and dust emissions, and lower labor costs by automating the conveying process. These systems also support cleaner and safer working environments by containing materials within the ductwork.

Capacities

Material Throughput: From a few pounds per hour to several tons per hour

Conveying Distance: From a few meters to over 500 meters, depending on system design and material type

Air Flow Rates: From 500 to over 20,000 cubic feet per minute

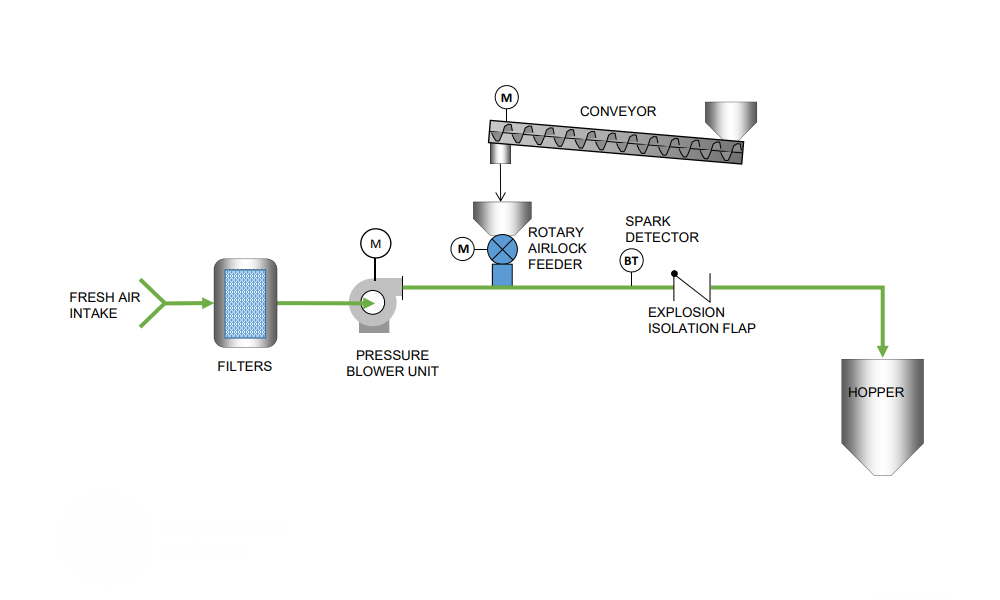

The system uses a blower or compressor to generate a stream of high-velocity air that carries materials through ductwork. Materials are introduced into the airflow at a feed point and conveyed through the ducts to a designated discharge point. The system includes components such as airlocks, diverter valves, and separators to control material flow, direction, and separation. The air velocity and pressure are carefully regulated to ensure efficient and consistent material transport, while minimizing wear and tear on the ductwork. By maintaining a continuous flow, the system ensures efficient material handling and transport, reducing downtime and improving overall productivity.

Related Systems

Please see the Pneumatic and Conveying Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.