Applications

Used in various industries, including manufacturing, aerospace, automotive, and construction. They provide direct high-pressure air for applications including aeration, agitation, pneumatic conveying, air curtains, and process gas handling.

Benefits

These systems offer reliable and efficient high-pressure air delivery, with enhanced control over air flow and pressure. They improve process efficiency, reduce energy consumption, and provide consistent performance for demanding industrial applications.

Capacities

Pressure Range: Typically delivers from 5 to over 50 psi

Flow Rates: From 1,000 to over 100,000 cfm

Stages: Multi-stage blowers can have two to eight stages, depending on the required pressure and flow

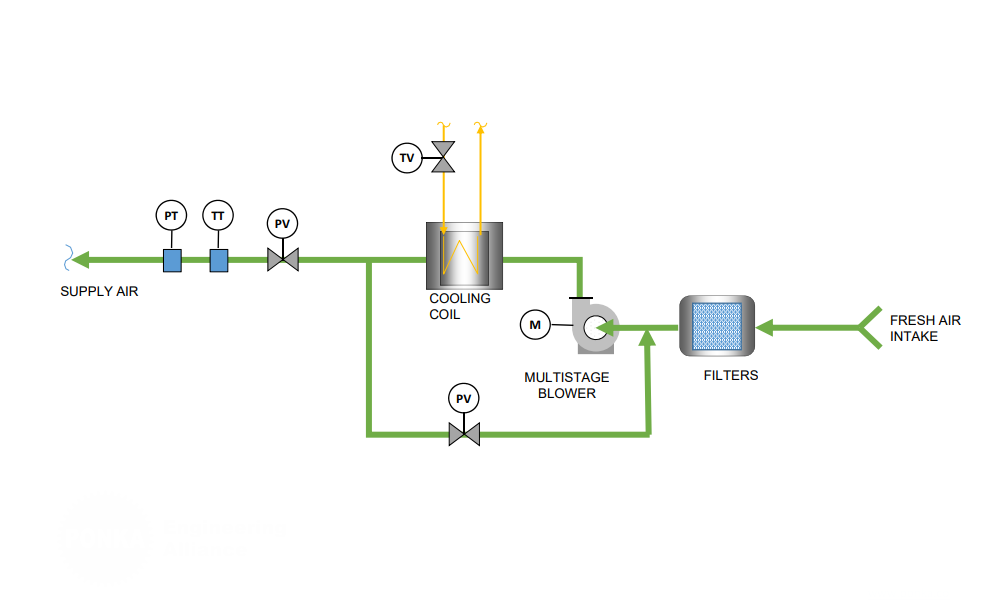

Air is drawn into the system and passes through filters and a multi-stage blower, where it is progressively compressed across several stages. Each stage increases the pressure incrementally, ensuring efficient compression and minimal energy loss. The compressed air is then directed through a distribution network to the required application points. The system includes control mechanisms to regulate air pressure and flow, ensuring precise delivery. The multi-stage design allows for higher pressures and greater control, making it ideal for applications requiring consistent and reliable high-pressure air.

Related Systems

Please see the Pneumatic and Conveying Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.