Applications

Used in paper mills to clean the paper web during production and manage airborne contaminants. They are essential for removing dust, debris, and pollutants from the paper surface and exhaust air, ensuring high-quality end products and maintaining a clean production environment.

Benefits

These systems improve paper quality by ensuring a clean surface, reducing defects and rejects. They enhance machine efficiency by preventing contamination build-up that can cause downtime and maintenance issues. The integration of wet scrubbers further ensures a cleaner working environment by capturing and neutralizing airborne pollutants, supporting compliance with environmental regulations and improving air quality in the mill.

Capacities

Cleaning Width: Ranging from 1 to over 10 meters

Cleaning Speed: Operating web speeds of 500 to over 2,000 meters per minute

Debris Removal Efficiency: Achieves up to 99% efficiency in removing dust, fibers, and other contaminants from the web surface

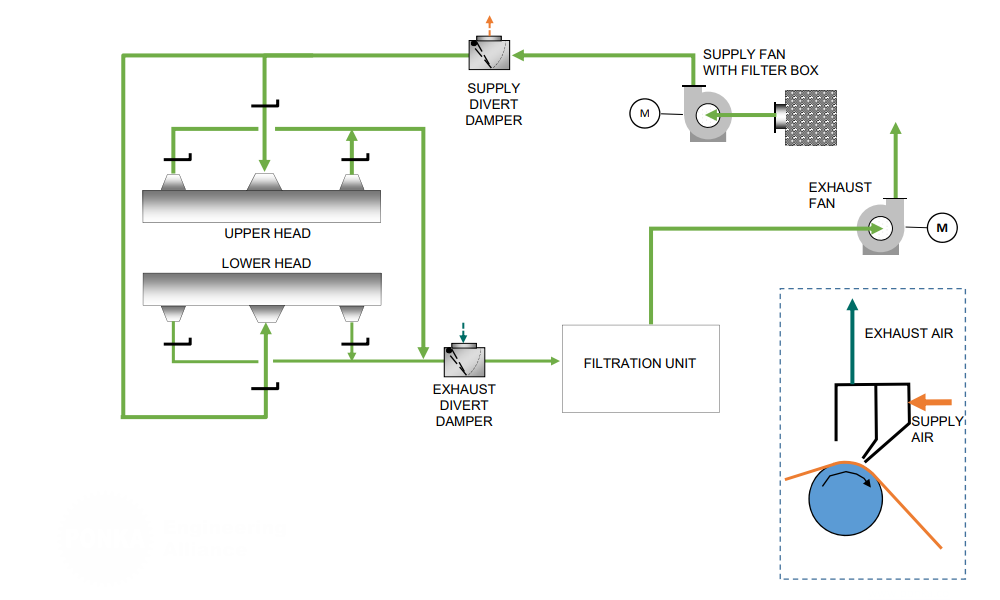

The web cleaner system consists of nozzles, brushes, and suction units placed along the paper machine. As the paper web passes through, air jets or brushes dislodge dust and debris from the surface, which is then captured by suction units. The system also incorporates a wet scrubber, where the contaminated air from the web cleaning process is directed. In the wet scrubber, water sprays capture and neutralize airborne contaminants, including dust and chemical vapors. The cleaned air is then released, while the collected debris and contaminated water are directed to a disposal or recycling system.

Related Systems

Please see the Scrubbing and Containment Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.