Applications

Used in tissue paper manufacturing to transport scrap tissue, offcuts, and trim waste to either a baler for compacting or a pulper for recycling. These systems are essential for efficient waste management and recycling processes, ensuring that waste tissue is handled in a streamlined and effective manner.

Benefits

These systems improve operational efficiency by automating the transport of tissue waste, reducing manual handling and associated labor costs. They support sustainability by facilitating the recycling of tissue waste back into the production process or compacting it for efficient disposal. Additionally, they help maintain a clean production environment, reduce downtime, and enhance overall plant productivity.

Capacities

Material Throughput: From a few pounds per hour to several tons per hour

Conveying Distance: From a few meters to over 500 meters, depending on system design and material type

Air Flow Rates: From 500 to over 20,000 cubic feet per minute

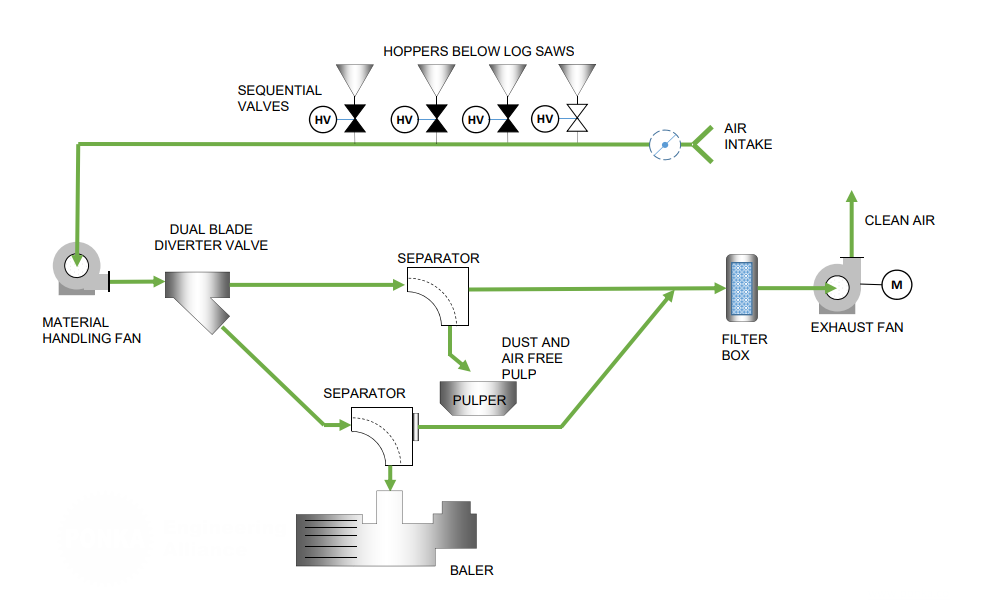

The system uses high-velocity air generated by a blower to transport tissue waste through a network of ducts. Waste tissue is collected at various points along the production line and introduced into the conveying system. The air stream carries the tissue waste through the ducts to a diverter valve, which directs the waste to either a baler or a pulper. The baler compacts the tissue waste into bales for easy handling and disposal, while the pulper recycles the tissue back into the production process. The conveying system ensures continuous and efficient movement of tissue waste, minimizing blockages and maintaining optimal production flow.

Related Systems

Please see the Pneumatic and Conveying Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.