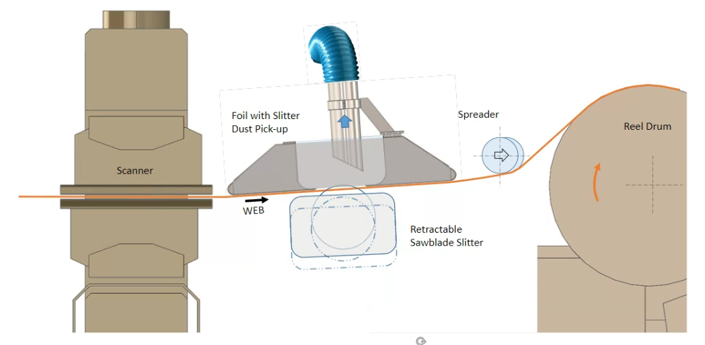

Applications

Used to support the web in the dry end and effectively collect dust generated by the saw blade slitter. These foils are essential in the paper manufacturing industry to maintain product quality and a clean working environment.

Benefits

These systems provide efficient dust collection from the saw blade slitter, reducing dust accumulation and maintaining a clean environment. The adjustable pick-up allows for optimization, while the cross-direction adjustment ensures precise positioning of the slitter. The polished foil surface minimizes drag, enhancing overall machine efficiency.

Capacities

Dust Collection: The slitter usually generates 3 to 8 lb/hr of dust

Adjustability: +/- 1” cross-direction adjustment of the slitter

Air Flow Rates: Adjustable pick-up for optimization

The passive foil supports the web in the dry end of the paper machine, with a wrap on the leading and trailing edges that adjusts based on the paper grade and speed to minimize drag. When the saw blade slitter is in use, it generates dust, which is collected by the foil. The adjustable pick-up optimizes dust collection, while the cross-direction adjustment allows precise slitter positioning. The polished surface of the foil ensures minimal drag, supporting smooth web handling and effective dust management.

Related Systems

Please see the Web Handling and Cleaning Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.