Applications

Optimizing machinery performance, ensuring worker safety, preventing contamination, controlling fumes, and protecting goods.

Benefits

Reduced operational costs, constant supply of clean air, climate control, improved worker safety, regulatory compliance, versatility, and reliability.

Capacities

Airflow: 1,000 to 100,000+ CFM

Heating: 100,000 to several million BTUs/hour

Steam: Handles low to high pressures (up to 100+ psi)

Filtration: Advanced systems for particulate and contaminant removal

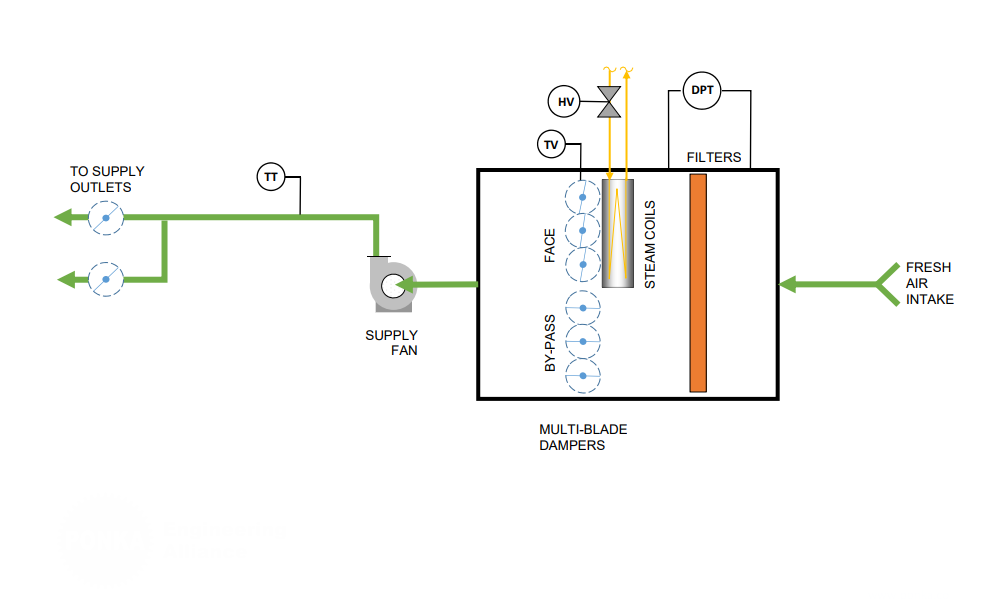

The industrial steam makeup air unit system operates by first drawing in outside or recirculated air and filtering it to remove dust and debris. The filtered air is then either heated using steam coils or cooled through refrigeration units, depending on the required temperature. To regulate humidity, the system adds or removes moisture as needed. Finally, the conditioned air is distributed throughout the facility via ducts or other air distribution systems, ensuring consistent and controlled environmental conditions.

Related Systems

Please see the HVAC and Air Handling Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.