Applications

Utilized in industries such as manufacturing, agriculture, mining, and food processing. These systems are designed to transport bulk solids, such as powders, granules, and small particles, through ductwork efficiently while separating the conveyed materials from the conveying air.

Benefits

These systems offer efficient material transport, reducing manual handling and associated labor costs. They minimize the risk of material contamination and loss, ensure a cleaner working environment by containing dust and particles, and enhance operational efficiency by automating the conveying process. Additionally, they support easy material separation and collection, improving overall process control.

Capacities

Material Throughput: From a few pounds per hour to several tons per hour

Conveying Distance: From a few meters to over 500 meters, depending on system design and material type

Air Flow Rates: From 500 to over 20,000 cubic feet per minute

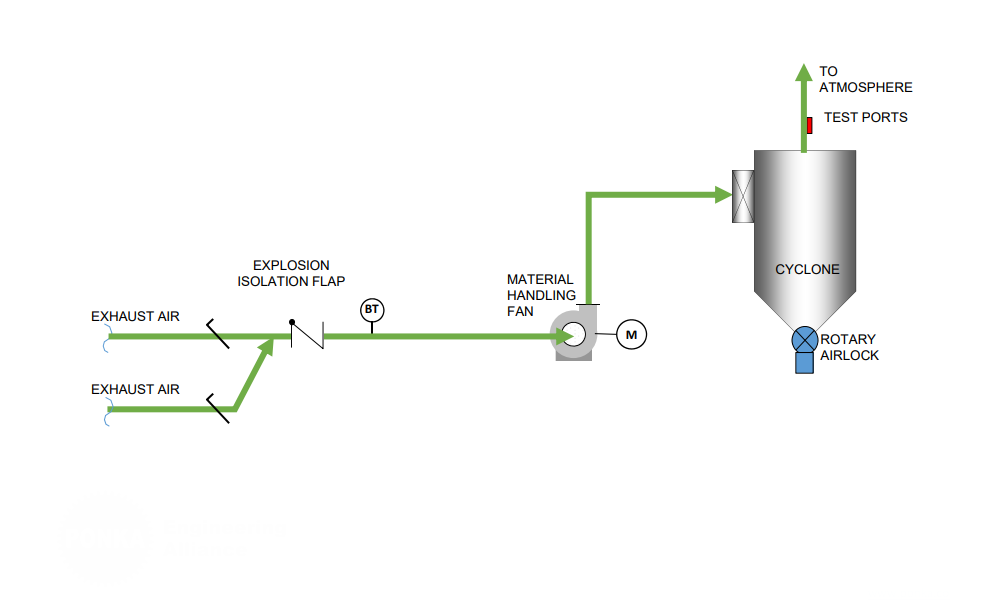

The conveying system utilizes a material handling fan to create a high-velocity air stream that transports solids through the ductwork. Materials are introduced into the ductwork where the air stream carries them to the cyclone separator. Inside the cyclone, centrifugal forces separate the solids from the air; the solids fall to the bottom for collection, while the cleaned air exits through the top. The material handling fan ensures consistent air velocity and pressure to maintain efficient material transport. This system design allows for continuous and reliable conveying of solids, with effective separation and minimal maintenance requirements.

Related Systems

Please see the Pneumatic and Conveying Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.