Applications

Used in various industries, including chemical processing, power plants, metal refining, and pulp and paper mills. They effectively remove particulates, acidic gases, and other pollutants from exhaust streams.

Benefits

Nye tray wet scrubber systems offer high removal efficiency for a variety of pollutants, versatility for different applications, and scalability for varying process sizes. They provide reliable operation with minimal maintenance and help facilities comply with stringent environmental regulations.

Capacities

Flow Rates: 1,000 to over 100,000 cfm

Removal Efficiency: Up to 99% for particulates and gaseous pollutants

Pressure Drop: Between 5 to 15 inWC, depending on the design and application

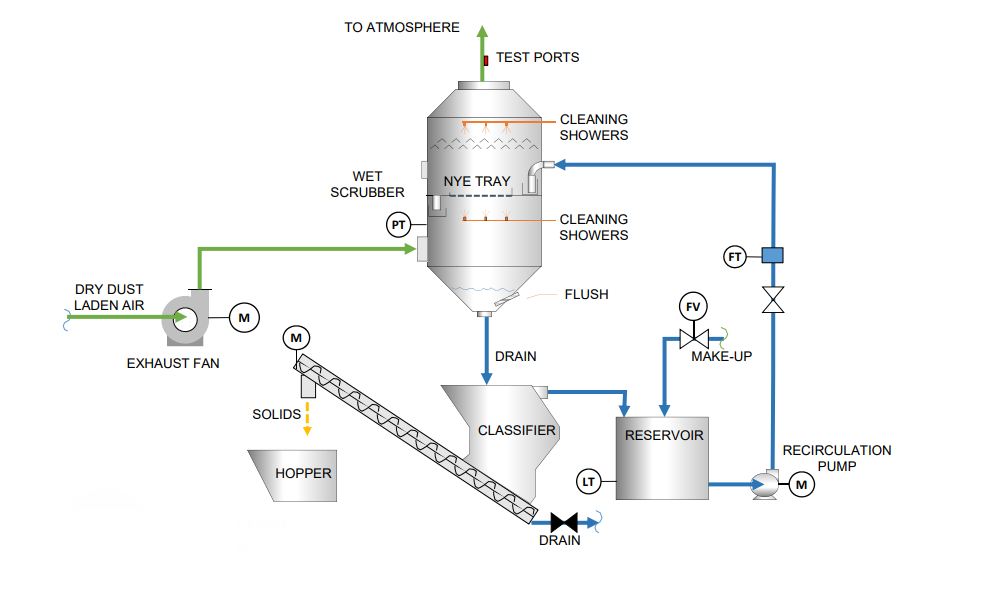

Contaminated gas enters the scrubber and passes through multiple perforated trays, where scrubbing liquid is sprayed. The gas-liquid contact promotes the capture of particulates and absorption of gases. The scrubbing liquid, now containing the pollutants, flows down through the trays to a collection sump, where it is removed for treatment or disposal. Clean gas exits the top of the scrubber, ensuring effective pollution control.

Related Systems

Please see the Scrubbing and Containment Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.