Applications

Used in various industries, including metalworking, chemical processing, and food manufacturing, to capture and control mist generated during operations. They are essential for processes that involve cooling, lubrication, and chemical reactions that produce airborne mist.

Benefits

Mist containment systems improve workplace safety by reducing slip hazards and respiratory risks associated with airborne mist. They enhance air quality, comply with environmental and safety regulations, and reduce equipment maintenance costs by preventing mist buildup on machinery.

Capacities

Flow Rates: 500 to over 50,000 cfm

Mist Capture Efficiency: Capable of achieving up to 99% capture efficiency for various mist types

Containment Capacity: Suitable for small to large-scale operations

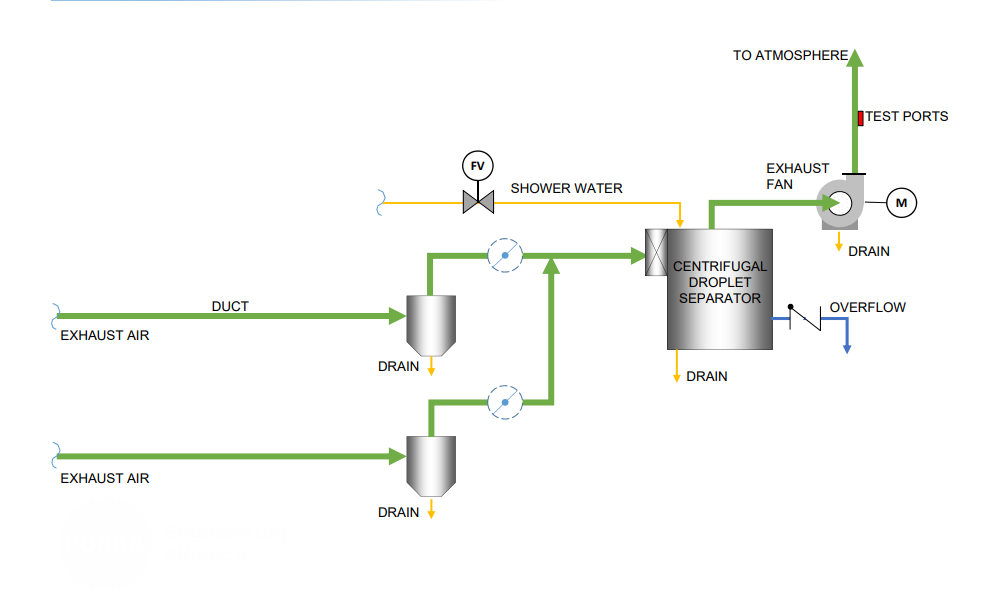

Contaminated air containing mist enters the system, where it passes through a series of filters or collection devices designed to capture mist particles. These devices can include mechanical filters, electrostatic precipitators, or centrifugal collectors. The captured mist is then separated from the air and collected in a reservoir or drainage system for proper disposal or recycling. Clean air is discharged back into the environment or recirculated within the facility, ensuring effective mist control and a safer working environment.

Related Systems

Please see the Scrubbing and Containment Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.