Applications

Used in various industries, including manufacturing, woodworking, and food processing, to efficiently collect and manage dust, debris, and other solid waste. These systems provide workers with convenient access points for cleaning and waste removal directly at the work site.

Benefits

These systems enhance workplace cleanliness and safety. They improve operational efficiency by minimizing downtime for cleaning and maintenance. The use of cyclone separators extends the lifespan of filters and reduces maintenance costs by pre-separating solids from the air stream. Additionally, hose stations provide flexible and convenient access for workers to perform localized cleaning tasks.

Capacities

Air Flow Rates: From 500 to over 10,000 cfm

Vacuum Pressure: From 5 to 50 inWC

Collection Capacity: Cyclones can handle solid waste loads from a few pounds to several tons per hour, depending on the system size

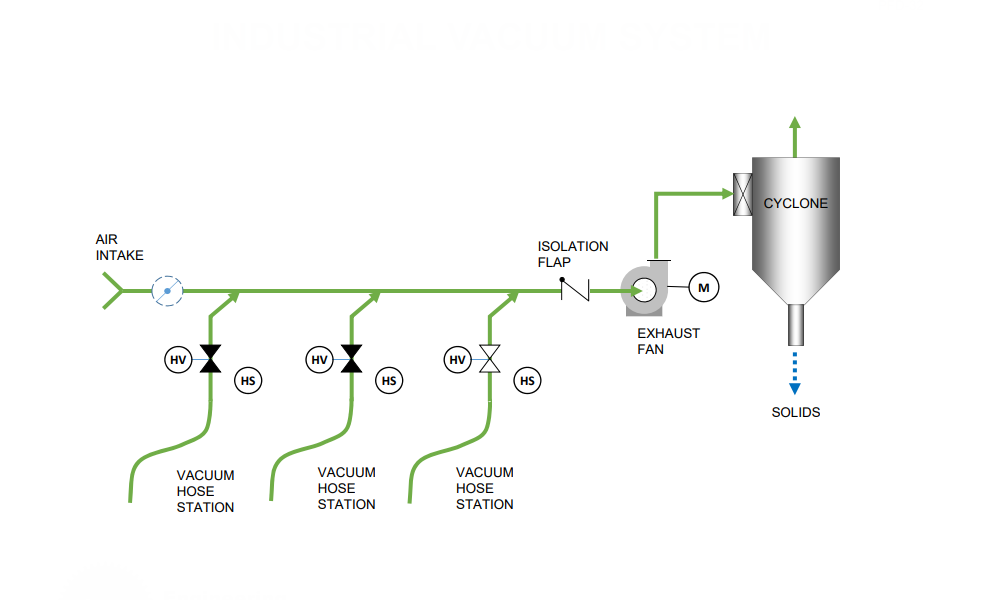

The system consists of a central vacuum unit connected to a network of hoses and hose stations strategically placed around the facility. Workers connect hoses to the hose stations to vacuum up dust and debris directly from their work areas. The vacuumed material is transported through the ductwork to a cyclone separator. Inside the cyclone, centrifugal forces cause the solid particles to separate from the air stream and collect at the bottom of the cyclone, while the cleaned air is exhausted or sent through additional filters for further purification. This process ensures efficient and continuous removal of solid waste, maintaining a clean and safe working environment.

Related Systems

Please see the Dust and Exhaust Control Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.