Applications

Used in industries such as wastewater treatment, pulp and paper, food processing, and petrochemicals to remove hydrogen sulfide (H₂S) from air emissions. These systems are crucial for odor control and maintaining safe air quality.

Benefits

H₂S packed bed scrubber systems provide highly efficient removal of hydrogen sulfide, significantly reducing odors and preventing equipment corrosion. They enhance air quality and ensure compliance with environmental regulations. These systems are durable and low-maintenance.

Capacities

Air Flow Rates: 500 to over 50,000 cfm

H₂S Removal Efficiency: Up to 99.9%

Packed Bed Volume: Customizable based on specific application needs

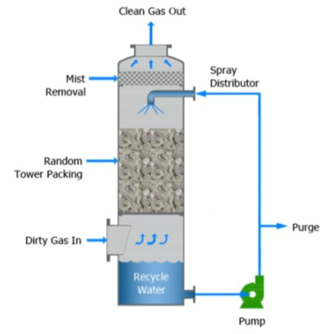

H₂S packed bed scrubber systems operate by passing contaminated gas through a tower filled with packing material. The gas enters the scrubber and moves upward through the packed bed, where it comes into contact with a scrubbing liquid. The liquid absorbs the H₂S from the gas stream. The packed bed provides a large surface area for mass transfer, enhancing the removal efficiency. The cleaned gas exits the top of the scrubber, while the scrubbing liquid is recirculated or treated and discharged. The system’s design includes control mechanisms to maintain optimal operating conditions, ensuring high removal efficiency and reliable performance.

Related Systems

Please see the Scrubbing and Containment Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.