Applications

Used in various industries, these systems effectively manage and remove moisture-laden air and contaminants, ensuring safe and clean working conditions.

Benefits

H₂S bio scrubber systems provide effective removal of hydrogen sulfide, significantly reducing odors and improving air quality. They are environmentally friendly, using biological processes to break down contaminants. These systems require low operational costs and minimal maintenance. The long media life enhances cost-effectiveness and system reliability.

Capacities

Air Flow Rates: 500 to over 50,000 cfm

H₂S Removal Efficiency: Up to 99.9%

Media Life: Typically 3 to 5 years before replacement

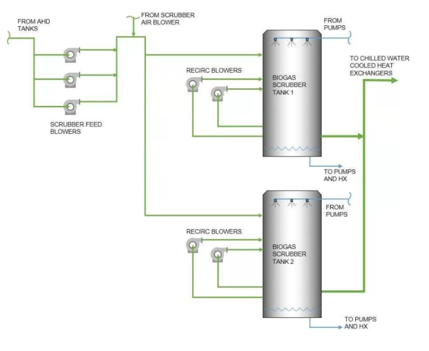

H₂S bio scrubber systems use a biological process to remove hydrogen sulfide from contaminated air. The air is passed through a scrubber tower containing a packed bed media, which supports the growth of specialized bacteria. These bacteria oxidize H₂S into harmless compounds like sulfuric acid and water. The contaminated air enters the system and flows through the media, where the bacteria break down the H₂S. Clean air is then exhausted from the system, and the liquid by-products are safely disposed of or reused. The system includes control mechanisms to maintain optimal environmental conditions for the bacteria, ensuring high removal efficiency and long-term operation.

Related Systems

Please see the Scrubbing and Containment Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.