Applications

Used in facilities such as mills and factories, particularly those with biofuel gensets. These systems manage and expel exhaust gases produced during generator operation, ensuring safe and efficient energy production.

Benefits

Industrial generator exhaust systems efficiently remove harmful exhaust gases, ensuring compliance with environmental regulations and maintaining air quality. They reduce noise levels through integrated silencers, enhancing the working environment. These systems are durable, capable of withstanding high temperatures, and customizable to fit specific generator setups.

Capacities

Exhaust Flow Rates: Customizable, typically ranging from 1,000 to 50,000 cfm

Temperature Handling: Up to 1,400°F (750°C)

Noise Reduction: Integrated silencers for noise control

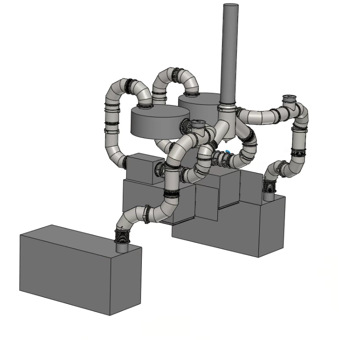

Industrial generator exhaust systems collect exhaust gases from the generator and channel them through a series of ducts and silencers. The exhaust gases pass through a muffler or silencer to reduce noise levels before being expelled outside the facility. The system’s ducts are designed to handle high temperatures and are often insulated to protect surrounding equipment and personnel. The exhaust flow is directed safely away from the work area, ensuring compliance with emission standards and protecting air quality. The system can be tailored to the specific needs of the generator and facility, ensuring optimal performance and safety.

Related Systems

Please see the Dust and Exhaust Control Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.