Applications

Used across various industries to manage and remove airborne dust particles. They are used in a variety of different applications.

Benefits

Dry dust exhaust duct systems significantly improve air quality by capturing and removing dust particles, reducing health risks and enhancing workplace safety. They are adaptable to various applications, offering flexibility and reliability. The systems are designed for easy maintenance and robust construction, ensuring long-term performance and durability. When equipped with separators, they provide additional dust separation efficiency.

Capacities

Air Flow Rates: 500 to over 50,000 cfm

Dust Collection Efficiency: Up to 99%

Duct Sizes: Customizable to fit different facility requirements and applications

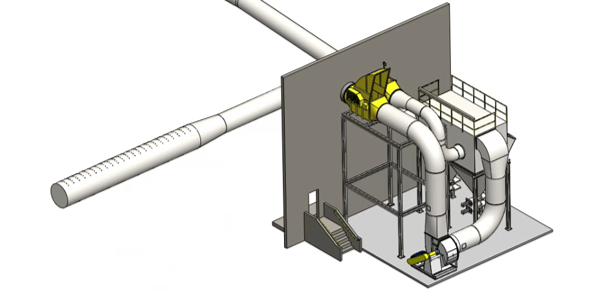

Dry dust exhaust duct systems utilize a network of ducts to collect and transport dust-laden air from various sources within a facility. High-capacity blowers and fans move the air through the ducts to a central exhaust point. Separators, such as cyclones or baghouses, are integrated as needed to enhance dust separation efficiency. These separators use centrifugal force or filtration to remove dust particles from the air stream. The cleaned air is then either exhausted outside or recirculated back into the facility. The system’s design includes strategically placed exhaust intakes to optimize dust capture and balance air flows.

Related Systems

Please see the Dust and Exhaust Control Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.