Applications

Used in various industries, including manufacturing, food processing, chemical production, and power generation. They recover waste heat from hot air exhaust streams to preheat water for use in processes such as cleaning, heating, and steam generation.

Benefits

These systems significantly improve energy efficiency by capturing and reusing waste heat, reducing fuel consumption and operational costs. Additionally, they support compliance with environmental regulations.

Capacities

Heat Recovery Capacity: Typically ranges from 10,000 to over 1,000,000 BTU per hour

Water Flow Rates: 10 to over 1,000 gallons per minute

Air Flow Rates: From 500 to over 100,000 cfm

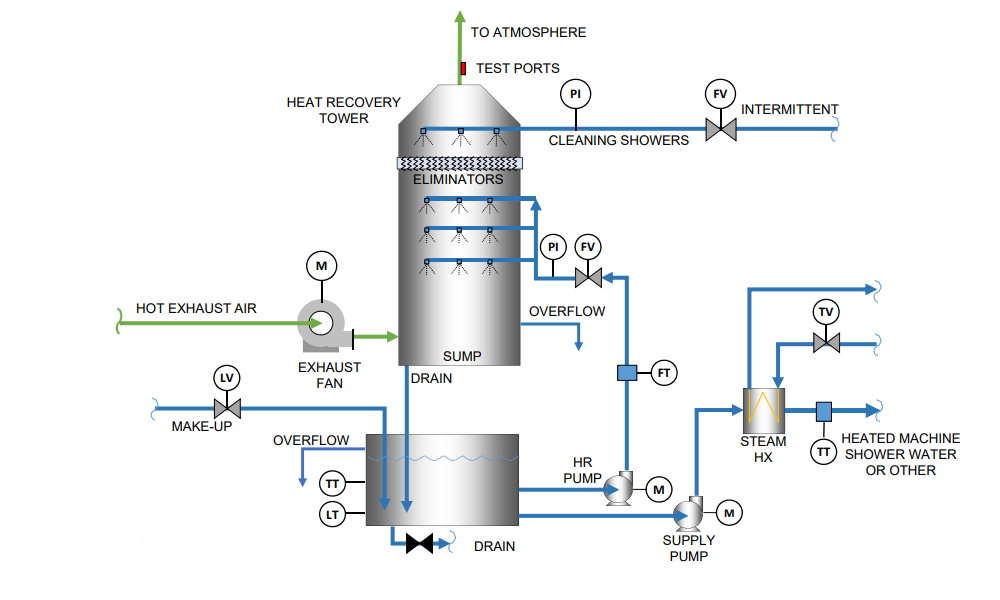

Hot exhaust air from industrial processes is directed through a heat exchanger where it transfers heat to incoming water. The heat exchanger consists of a network of tubes or plates that facilitate efficient heat transfer. The heated water is then stored in a reservoir or sent directly to processes that require hot water. The cooled exhaust air is vented out, while the recovered heat provides a valuable energy source for the facility. Control systems regulate the flow of air and water to optimize heat recovery and ensure consistent performance.

Contact us for more information or to discuss your application and receive an estimate.