Applications

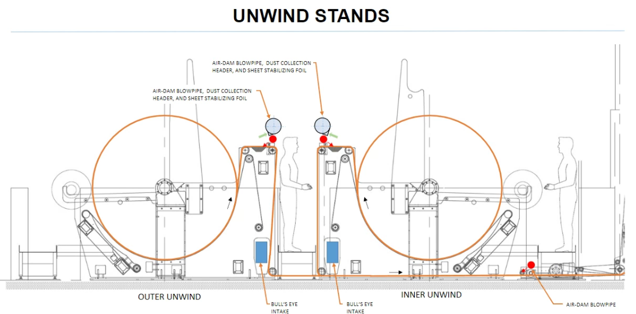

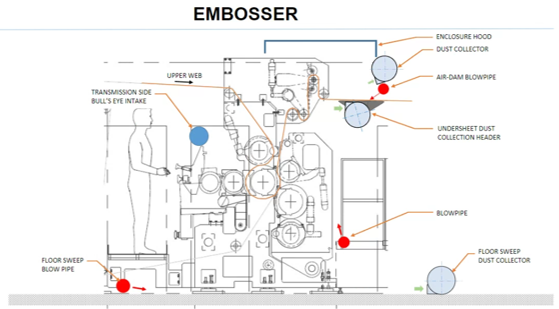

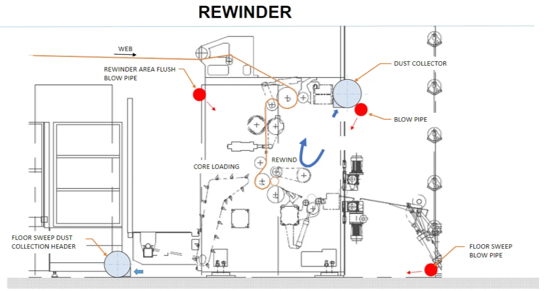

Industrial web control and dust control systems are essential for paper converting lines, ensuring precise handling of paper webs and effective dust management. These systems are used in industries such as paper manufacturing, printing, and packaging to maintain product quality and a clean working environment.

Benefits

These systems provide efficient web control, preventing issues like web breaks and misalignment. Dust control improves air quality, protects machinery, and ensures a clean work environment. The design is simple yet effective, with accessible exhaust intakes and adjustable flows for optimization. Components are heavy-duty and built to last, offering easy maintenance access.

Capacities

Air Flow Rates: From 1,000 to over 50,000 cfm

Containment Velocities: Designed to achieve velocities that effectively contain dust without causing web instability

Coverage Area: Adaptable to various widths and lengths of paper converting lines

Air is exhausted and supplied in strategic locations, balancing air flows with consideration to the moving surfaces of the paper webs. This design ensures the majority of dust is contained while maintaining web stability. The system achieves containment velocities without causing web instability and features adjustable flows and geometry for fine-tuning. All components are easily removable for maintenance access. The equipment is of heavy-duty construction, ensuring durability. The entire design process is done in 3D, utilizing 3D scans of existing equipment to ensure precise integration and functionality.

Related Systems

Please see the Web Handling and Cleaning Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.