Applications

Utilized in paper mills to process paper waste, or “broke,” generated during production. These systems separate usable fibers from the waste, allowing for efficient recycling back into the production line.

Benefits

Broke separator systems enhance resource efficiency by maximizing fiber recovery and reducing waste. They support sustainability goals, lower raw material costs, and improve overall production efficiency. By effectively managing and reprocessing paper broke, they help maintain continuous production.

Capacities

Flow Rates: 500 to over 10,000 gallons per minute

Separation Efficiency: Achieves high separation efficiency, recovering up to 95% of usable fibers from the waste stream

Processing Capacity: Designed to process various types of broke, including fine paper and cardboard

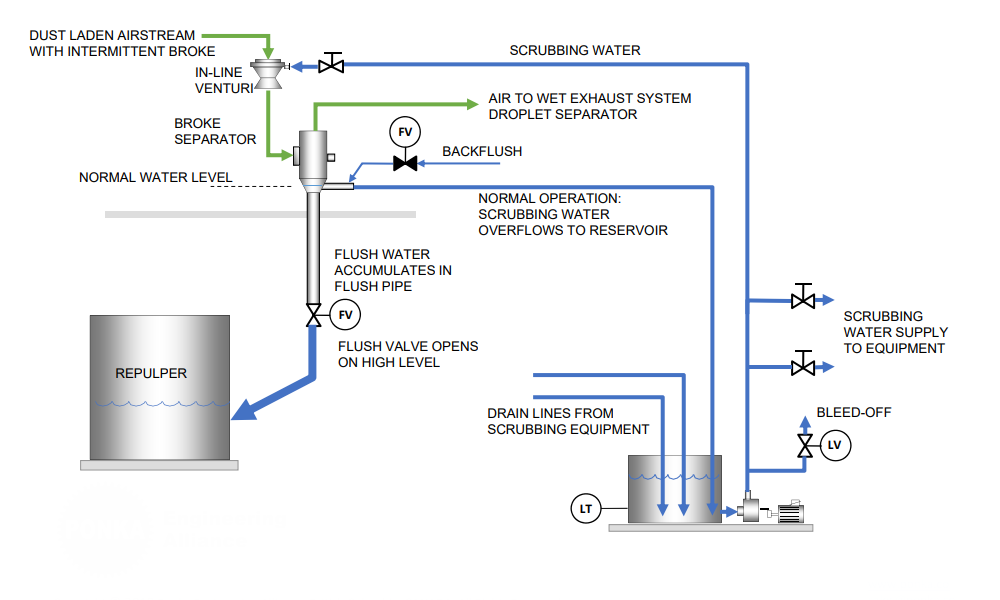

Paper broke is collected and mixed with water to create a slurry, which is then fed into the broke separator. The separator removes contaminants and separates usable fibers from the waste. The cleaned slurry, containing recovered fibers, is reintroduced into the paper production process. Contaminants are disposed of or treated accordingly. This process ensures minimal material loss and efficient resource utilization.

Contact us for more information or to discuss your application and receive an estimate.