Applications

Used in industries such as manufacturing, mining, cement production, and power generation to control air pollution. These systems are essential for capturing and filtering out dust, smoke, and other particulate matter from industrial exhaust streams, ensuring compliance with environmental regulations.

Benefits

Baghouse systems improve air quality by effectively capturing and removing airborne particulates, protecting worker health, and reducing environmental impact. They support compliance with stringent air quality standards and regulations, minimize downtime by preventing equipment fouling and wear, and enhance operational efficiency by maintaining cleaner work environments.

Capacities

Air Flow Rates: From 1,000 to over 100,000 cubic feet per minute

Filtration Efficiency: Achieves particulate removal efficiencies of up to 99.99%, depending on the filter media and system design

Dust Load Handling: From a few grams to several kilograms per cubic meter of air

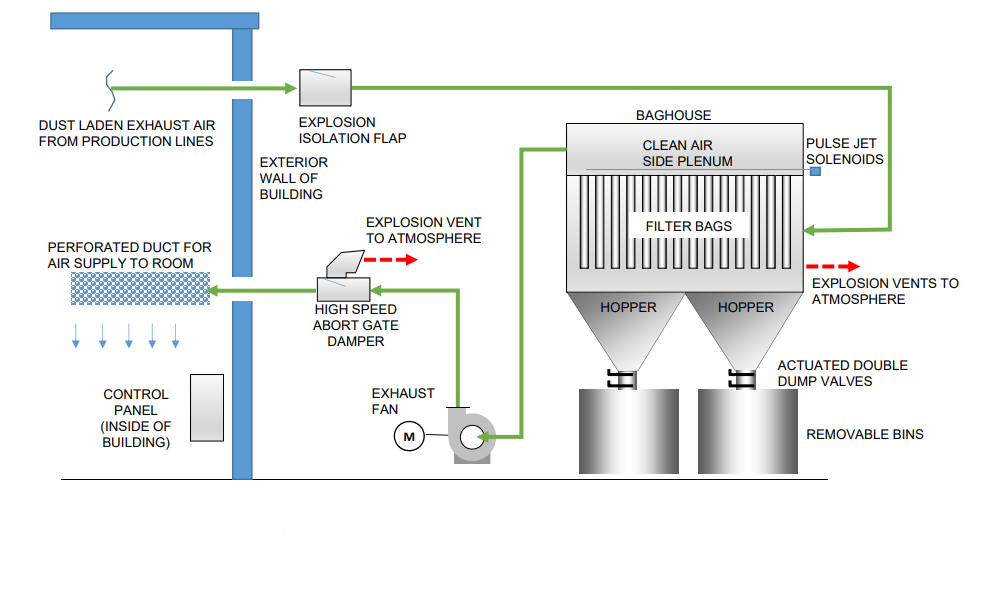

A baghouse system operates by drawing polluted air into a chamber where it passes through a series of filter bags. These bags are made of fabric designed to capture fine particulates. As the air flows through the bags, dust and other particulates are trapped on the surface of the filter media, while the cleaned air exits through the other side. Periodically, the system initiates a cleaning cycle, where compressed air is pulsed through the bags to dislodge the collected dust, which then falls into a hopper for collection and disposal. The continuous operation of the baghouse ensures effective and efficient particulate removal, maintaining clean air emissions and protecting the environment and workplace.

Related Systems

Please see the Dust and Exhaust Control Systems page for a list of the related systems.

Contact us for more information or to discuss your application and receive an estimate.